STC News

Milestones/History

Support Beam

STC100 & STC100W

STC150

STC200

SOAR300

SOAR500

ET Micro Grid

Description

Testimonials

Videos

Animations

Funding

Actions & Partners

SkyTrain Corporation - Investor Center

![]()

|

|

STC News Milestones/History Support Beam STC100 & STC100W STC150 STC200 SOAR300 SOAR500 ET Micro Grid Description Testimonials Videos Animations Funding Actions & Partners |

SkyTrain Corporation - Investor Center

|

|---|---|

|

Energy; the background:

|

Starting at the Guenther's Marina Complex, in 1986, including a Marine Dry Storage and repair which also also included a

Design and Build machining operation, Suncoast Engineering was the genesis for boat transportation, and began as they designed

an overhead boat carrying device connecting salt and freshwater communities over several roads in Hernando County, Florida, USA. In 1994, after several engineering system improvements in the marina, Suncoast Engineering desired to verify its findings and engineering concepts for transportation design. Armed with that task, Mr. Guenther made appointments and took his concepts to several Universities. Included were University of South Florida, Illinois Institute of Technology and Florida Institute of Technology. As anticipated, all three verified the validity of Mr. Guenther's engineering designs and concepts, suggesting grants.

|

Subsequently, Mr. Guenther closed his manufacturing and machine shop in order to expand his work and objectives on pursuing

the new Transportation Technology Concepts on a full time basis.

The company's name was changed to Sky Train Corporation in 1995, to reflect the mission at that point.

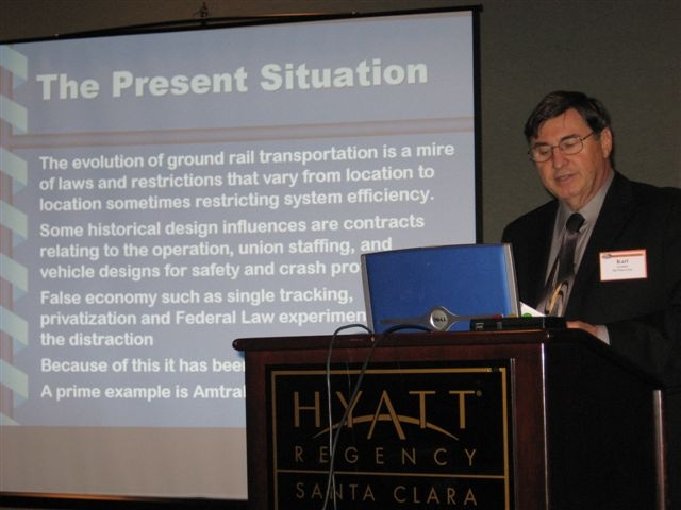

November 8- 9, 2006 Energy Venture Fair VII, Incorporating Clean and Environmental Technologies, Hyatt Regency, Santa Clara, CA.

Karl Guenther's presentation was accepted as STC's Energy Saving submission for approval, allowing it to display information to investors. |

|---|

Our Vision Of Energy (VOE):The next important issue is creating a vehicle that is light enough so that maximum energy reuse is feasible. Our model constructed in 2003 uses regeneration, the reclamation of the energy of stopping. Devices such as flywheels, capacitors and batteries are limited as to how much energy can be quickly saved. Present vehicles by legislation are too heavy and only a portion of the savings can be recycled at varying loss levels. Our lighter vehicles use regeneration. |

Rule: the more stops per hour/day the greater the savings, taxicabs, short distance rail and busses should be a public focus,

reducing the community carbon footprint.

The running surface interface is a major problem in today's societies. While rubber tires allow rough road construction they consume

up to 10 times, 1000% more energy consumed even on smooth roads compared to steel wheels on steel rails. Another large destroyer of energy are the mechanical systems such as transmissions and differential gearing. The electric motor's speed reducer on a rail vehicle uses 5% to 7% of the transmitted energy over the acceleration and energy recapture cycles. These deficits occur at every start stop cycle and it is a major issue. |

One solution is the use of direct drive motors or motor wheels. For high speed transportation wind resistance becomes a consumer of energy. Flight consumes two times the energy of slower speed rail transportation. The use of conversion to energy through means such as piston engines, micro or other turbines each have efficiency ratings and can generally be accomplished more efficiently at stationary power plants where co-generation can occur.

A hidden consumer of energy is transmission losses due to the conductors used. |

| Sky Train Corporation | Webmaster: Ove Johnsson - Johnson Consulting | Last Updated: 2017-02-13 |